Thanks for scanning into our holiday case study!

We’re happy to show off the goods from our partners over at Oaktown Spice Shop

+ take you through some of our variable data solutions.

This holiday label started out as a blank or fully-variable data label. We engineer this type of label for customers that don’t need any pre-printed information. These labels are the most cost efficient way to utilize variable data printing. We have hundreds of die sizes in house and new custom dies are always only a few days away. We can cut custom sizes on Thermal Transfer, Direct Thermal or Inkjet Materials. This specific label was cut using a TT imprintable Matte BOPP.

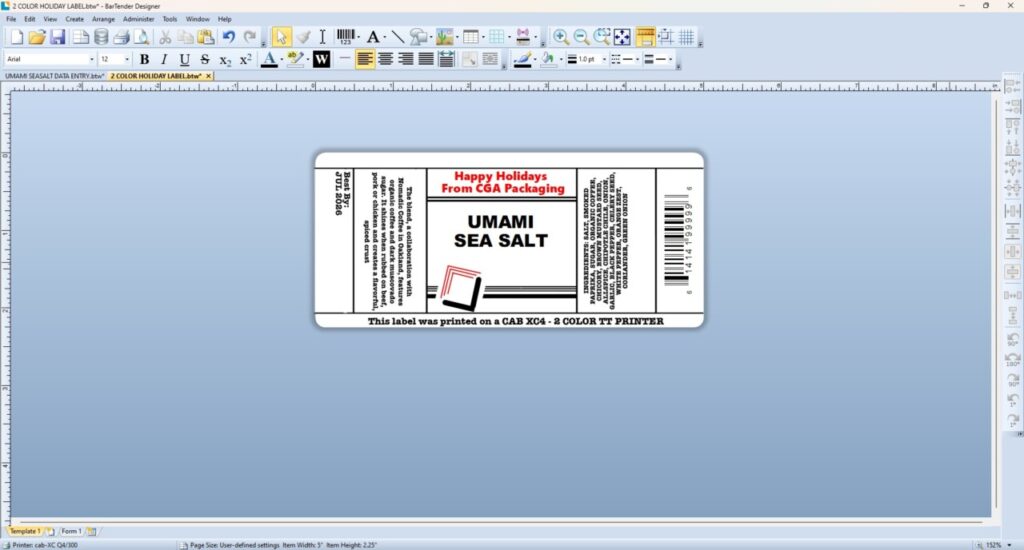

The variable data was then laid out and managed using Seagull Scientific’s Bartender Label Software. We help our customers to lay out their information using the designer. Pro-users then move on to utilize either data entry forms or database connections quickly change their variable data. Bartender can even handle multi-color label designs such as this holiday label or GHS labels.

The labels were then printed on the CAB XC Q4 Dual Printhead Thermal Transfer Printer. This unique printer utilizes two 300 DPI printheads to allow our customers to further customize their variable data labels. This configuration is popular with GHS Labelling, but can expand branding options for any consumable industry.

We stock many different colors of ribbons to offer a unique look for your products.

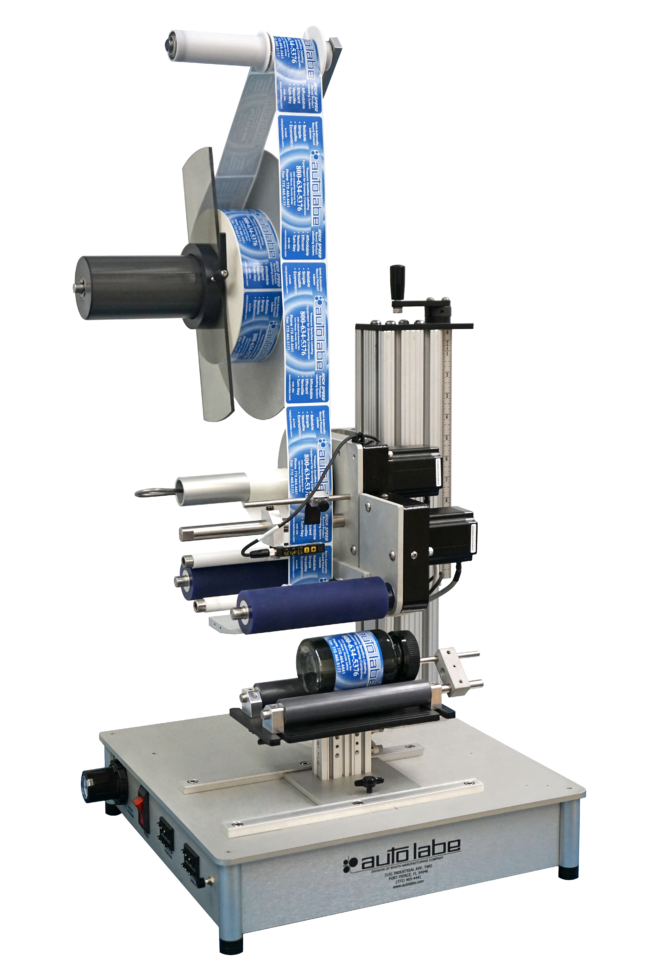

The product labels were then applied using the Autolabe 550S, Semi-Automatic round product label applicator. This semi-automatic applicator allows users to increase their throughput and reduce touchpoints. The product rollers are adjustable; from small vials for the biotech industry, up to large jars for food manufacturing.

The lid labels were printed using the CAB Squix Thermal Transfer Printer. This 600 DPI, middle-aligned printer is perfect for printing incredibly precise variable data. This model is a perfect fit for anyone who needs to print detailed information and small scannable objects onto any size label.

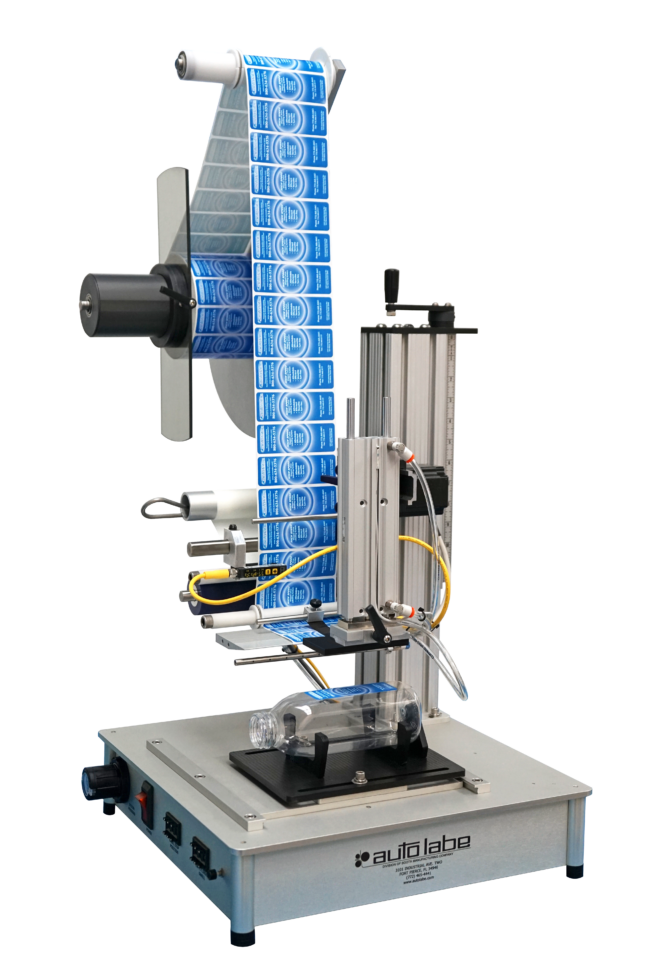

The lid labels were then applied using the Autolabe 560S, Semi-Automatic Tamp down applicator. This unit utilizes a custom sized, vacuum tamp head to put labels onto lids, boxes or any flat/near flat object. The small form factor and ease of use are major selling point for this cost effective way to increase throughput and reduce touchpoint costs.