Blog

Your Source for the Latest Packaging & Print Industry Insights and Trends

Our Blog is a dynamic space where we share industry insights, expert tips, and the latest trends to keep you informed and inspired on your packaging journey.

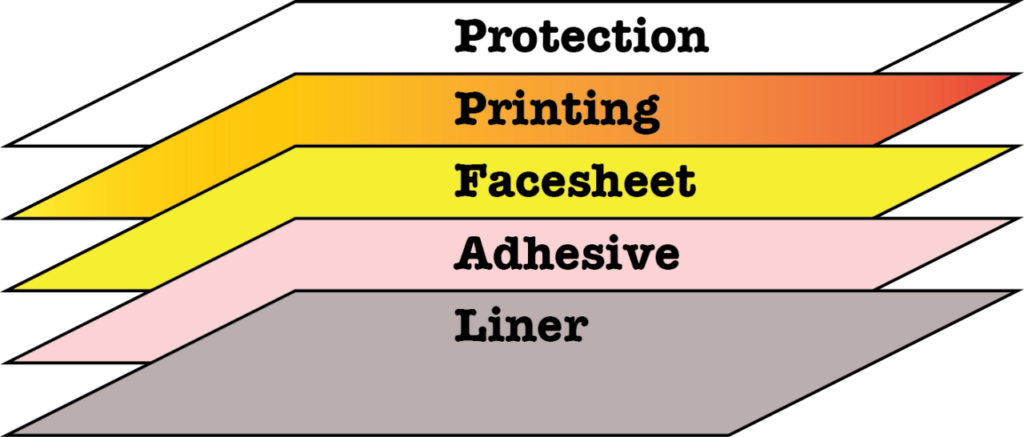

Label School – Face Sheets

Face Sheets!

Paper or synthetic—what’s the right choice?

While paper and synthetic are the two basic choices, there are many choices for each. There are many different types of synthetic materials; from new plant based films to traditional plastics. The same goes for papers; from 100%PCW to traditional estate stocks. Let’s examine the differences between paper and synthetic in more detail.

Paper substrates

Paper substrates are typically used for indoor labels with a relatively short lifespan and limited exposure to moisture, chemicals, temperature extremes and abrasion. However, paper substrates can be combined with a synthetic laminate for additional permanence. Topcoats such as varnish or aqueous coatings can also be used to make paper more durable. Paper comes in coated and uncoated finishes and is available in a wider range of colors than synthetic substrates. In general, paper substrates cost less than synthetic ones, often making paper the best value for less demanding applications. Many paper substrates can use recyclable material, making them more eco-friendly.

Synthetic substrates

Synthetic substrates are typically used for most outdoor applications or indoor applications with exposure to a variety of harsh conditions.

- Polyester is durable but rigid and can typically provide two to five years of outdoor service. Polyester films are available in a wide range of thicknesses starting at 1 mil.

- Vinyl substrates conform well to curves and provide an outdoor service life of seven-plus years. A 4-mil vinyl is the most commonly used thickness.

- Polypropylene is moisture resistant and temperature variable, making it popular for consumer goods like plastic soft drink containers. With a useful lifespan of approximately six months to two years, polypropylene is used for a number of indoor or short-term outdoor applications. Polypropylene films are typically less costly on a unit area basis than other films.

Feel free to reach out to sales@cgapackaging.com if you have any questions about face sheets.

Other Articles

Label School – Liners

Liners! Liners are the foundation of nearly all label substrates. There are a few...

Welcome to Label School

la·bel/ˈlābəl/noun1. A small piece of paper, fabric, plastic or similar material attached to an...

Label School – Adhesives

Adhesives! The adhesive layer of your label material may be the most important. Label...